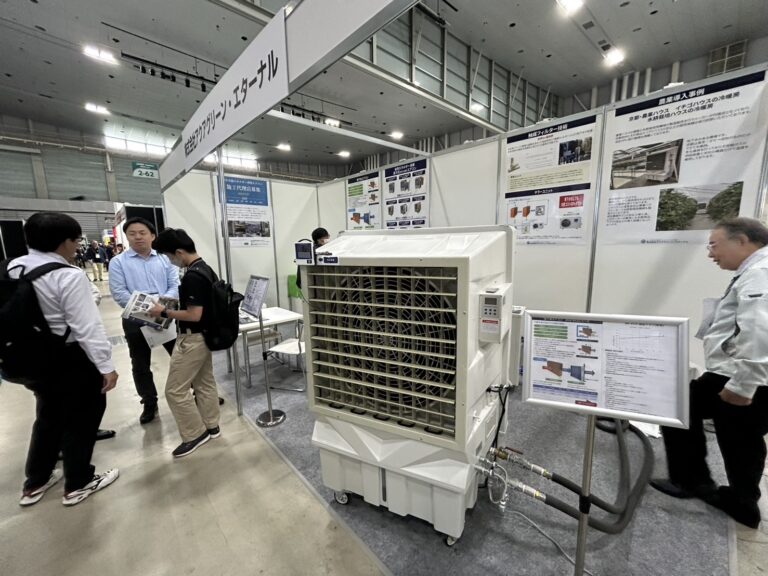

Case study: A factory in Nara Prefecture

Introducing area: Nara Prefecture

Construction period: 1 month

Equipment: 6 stainless steel pad and radiator combination units with chiller unit

We have introduced this system as a model at our affiliated factory (resin molding) in Nara Prefecture.

This is an energy-saving heat source cooler with a two-stage mechanism that is original to our company.

Because this factory is located in an area where groundwater cannot be extracted, a small chiller is used to cool the heat source water, but the power consumption reduction effect has been confirmed. The amount of power consumption is still being monitored continuously.

Humidity is also controlled through integrated control, achieving both energy savings and environmental improvements at the facility.

Tours are also available, so please feel free to contact us if you are in the area!