Heat Recovery System

The Sustainable Development Goals (SDGs), formulated by the United Nations in 2015, set 17 goals to create a brighter future while protecting our lives and the planet. Environmental and energy issues are one of these, and the seventh goal is listed as "Affordable and clean energy for all." In addition, electricity prices continue to rise due to the situation in Ukraine, the soaring import prices of liquefied natural gas (LNG), and the suspension and decommissioning of power generation facilities.

We are engaged in business activities that are useful to companies by solving environmental problems and saving energy. Utilizing waste heat from factories is one of them.

There are various types of waste heat in factories. Each line is small, so heat recovery is difficult, but we can handle designs for small-scale projects.

We will introduce some representative examples.

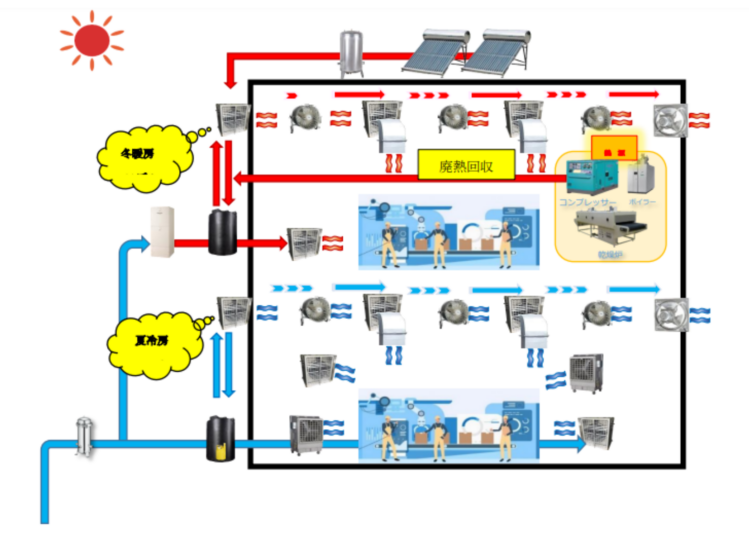

Utilization of compressor waste heat

Compressors installed in utilities such as factories constantly emit waste heat of about 70℃, which is discharged outdoors to prevent the compressor from overheating. Our radiator-type heat exchanger converts this heat into hot water and uses it for heating.

Utilization of boiler flue gas

The waste heat from the boiler is at a high temperature of over 300°C. It is possible to recover this heat by converting it into hot water using our radiator-type heat exchanger, just like compressor waste heat, or by heating it to a slightly higher temperature using a heat transfer medium. The recovered heat can be used for heating or for heating the boiler's feed water. Alternatively, it is possible to modify the boiler so that this waste heat is returned to the boiler's combustion intake air, which can increase the boiler's combustion efficiency.

Heat recovery from blowdown water and hot spring water in boiler tubes

Usually, heat recovery is performed for steam drain, but for the blowdown water of the boiler tube body, heat recovery is not usually performed because it would cause crystals to precipitate. However, our company's non-clock type heat exchanger for slurry makes it possible to recover heat while preventing scaling.

As a simple method, we can also suggest a method in which a stainless steel flexible pipe is coiled inside a stainless steel tank and used for heat exchange, which allows scaling to be easily washed off with a high-pressure washer, etc. This method is also proposed for hot spring heat recovery, etc.

Dryer heat recovery

For heat recovery from vacuum dryers, we can propose using a heat pump, which allows for heat recovery of approximately 70%.

In the case of hot air drying, it is common to use a heat exchanger to recover the released wind heat, but because this only recovers sensible heat, only about 151 TP3T of heat can be recovered. Our company has a method that enables recovery of latent heat by arranging heat exchangers in multiple stages. In addition, when using technology that utilizes the Föhn phenomenon, for which we hold exclusive patent rights, it is possible to recover latent heat as well, bringing the heat recovery rate up to about 701 TP3T.

We would like to collaborate with companies that are willing to maintain confidentiality regarding this special technology that applies the föhn phenomenon, so please feel free to contact us.

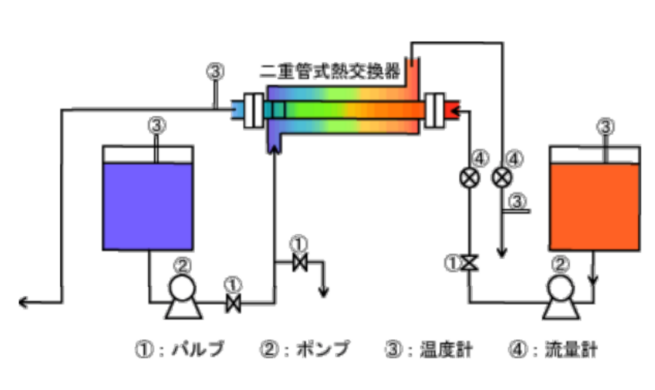

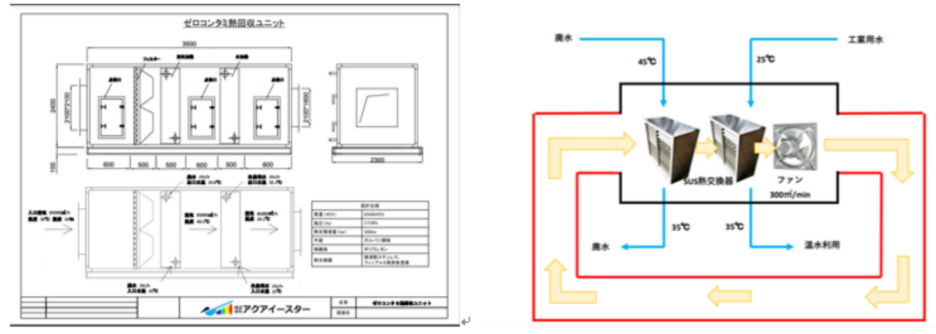

Heat recovery from wastewater (zero contamination heat exchanger)

Food factories and other facilities often have heating and sterilization processes at temperatures above 100°C. To recover heat from wastewater, plate heat exchangers are generally used, but if the metal parts of the heat exchanger crack or leak, there is a risk that contaminants will be mixed into the product line along with the recovered heat, so cases in which heat recovery is possible have been limited.

However, through joint development with a major food factory, we have succeeded in developing a zero-contamination heat exchanger that eliminates contamination by creating an air layer between the heat exchangers.

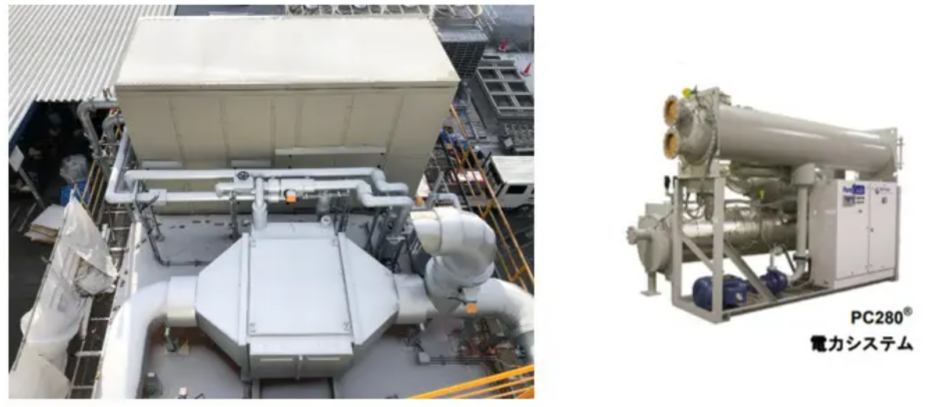

Heat recovery from combustion furnaces, etc.

The waste heat from combustion furnaces reaches around 700℃, and recovering this heat is an issue, especially at industrial waste incineration plants.

We have partnerships with manufacturers that perform binary power generation, and can also design large-scale equipment, so please feel free to contact us.

We can also make various other proposals depending on the facility. Please feel free to contact us.

Request a catalogue

Aqua Green Eternal uses renewable energy.

We sell ultra-energy-efficient air conditioners.

inquiry

Questions about renewable energy, energy conservation, air conditioning, etc.

Please feel free to contact us.